Common equipment lubrication in beverage factories

Common equipment in beverage factories: raw material workshop containing sugar, extraction and other mixing tank reduction gearbox, homogenizer packaging workshop crystallizer, injection molding machine (preform machine), bottle blowing machine

Filling workshop: aseptic filling machine, hot-filling filling machine

Packing workshop: capping (capping) machine, labeling/sleeving machine, film wrapping machine, palletizing machine for packing

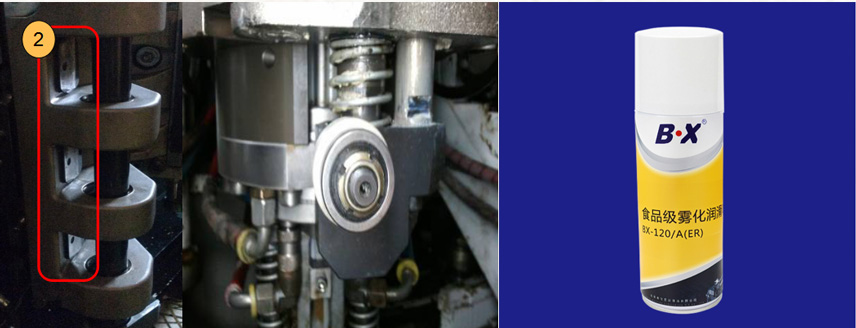

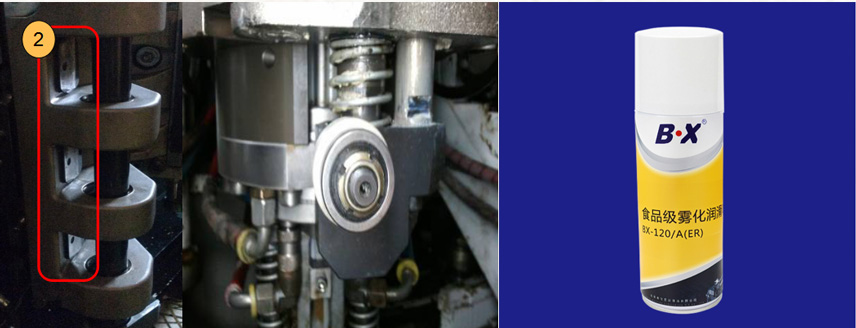

Blowing machine: lubrication parts-(1) heating furnace core shaft and shift fork, clamping rod / clamping rod / manipulator clamp bushing, heating furnace chain; (2) automatic lubrication system / clamping system / each guide Wheel; (3) center column;

Lubrication difficulties: high speed will throw grease, the clamping structure is worn out, and the centralized lubrication pumping is not smooth

Lubrication solution: BX-120/A(ER) food-grade spray, which can solve (1) grease slinging at lubrication parts, extend maintenance intervals, and extend equipment life; BX-300/G(1) food-grade high-performance lubrication Solve the problems of (2) the pumping of grease at the lubrication part does not smoothly cause the machine to alarm and stop, and the equipment wears out. BX-300/E(SG) food grade perfluoropolyether grease can solve the problem of product high temperature and lubrication maintenance interval.