The automobile glass lifting system is an important part of the opening and closing parts of the entire vehicle, and it plays an important role in the quality of the closed part system and the entire vehicle. Glass lifter is a lifting device for automobile door and window glass, mainly divided into two categories: electric window lifter and manual window lifter. Nowadays, the lifting of doors and windows of many cars generally uses button-type electric lifting methods, using electric glass lifters.

The position of the worm gear of the electric glass lifter needs to be coated with silencer grease to reduce the friction index generated during operation and enhance the lubricity, which can reduce the running noise for a long time and extend the service life. For worm gears with different rotation requirements, the lubricating greases used are not the same. We can provide greases with different properties according to the requirements of the customer's product rotations, materials, high and low temperatures.

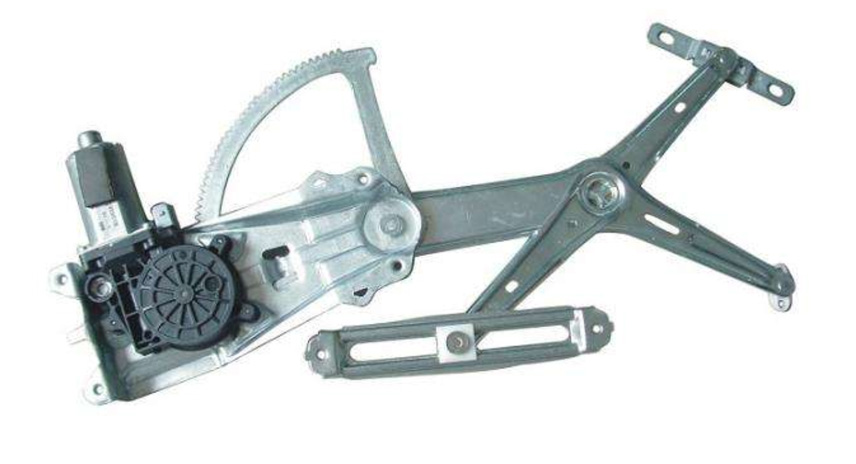

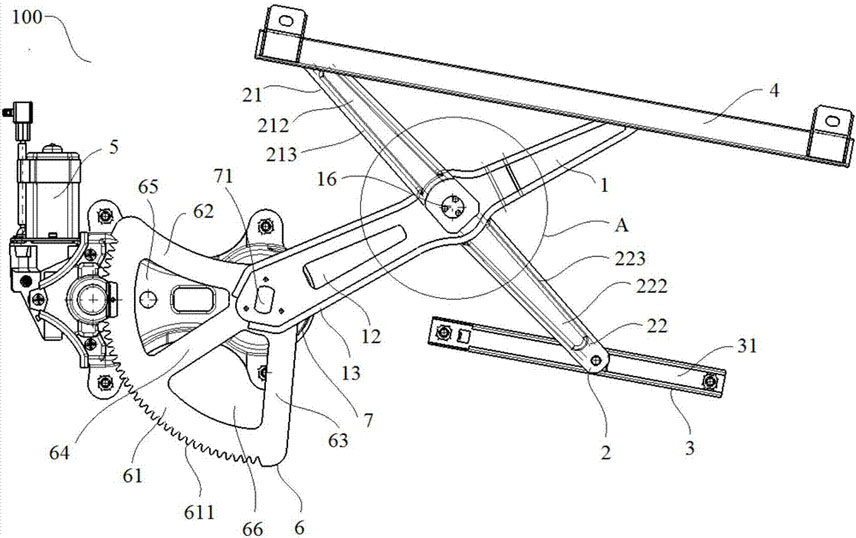

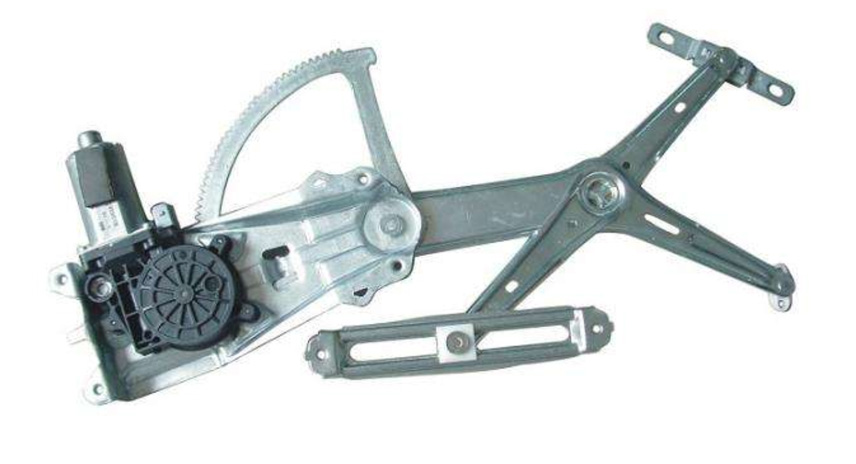

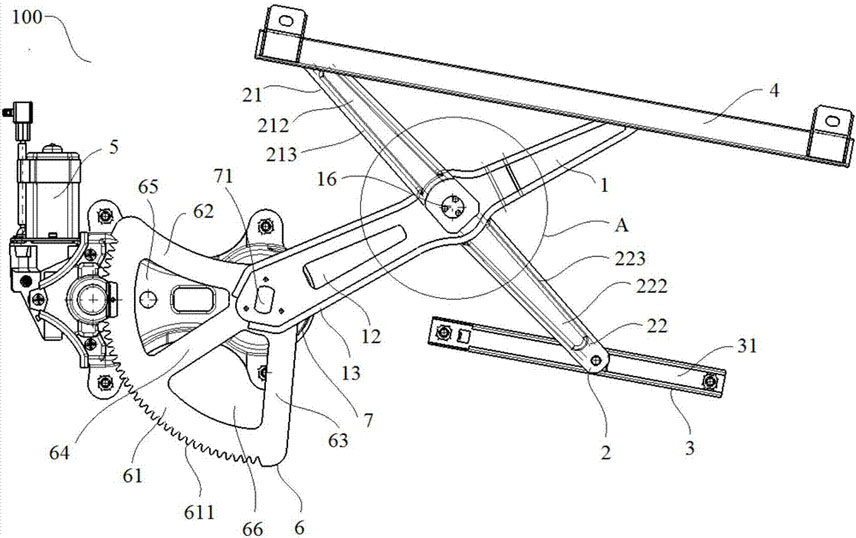

The composition of the car glass lifter:

The automobile glass lifter is composed of a motor, a worm gear, a shock-absorbing spring, a cable, a clamper, and a glass lifter guide rail. For example, the main switch controls the opening and closing of all doors and windows by the driver, and the sub-switch on the inner handle of each door is controlled by the occupant to open and close each door and window glass, which is very convenient.

Types of worm gears:

There are many types of worm gears for automobile glass lifters, and the motors and gears of the same model are exactly the same, so there is no need to distinguish them when installing. According to the requirements of the product, choose motors with different torques and voltages. Most of the worm gears will use metal materials and a small number of them will use plastic materials, such as powder metallurgy/iron and steel/nylon materials. The specifications are also based on the motor configuration.

The role of worm gear:

The worm gear DC deceleration motor is based on the ordinary DC motor with a deceleration mechanism, using the worm wheel and worm as the power transmission mechanism, the original rotation speed of the motor is reduced to the desired rotation speed, and a larger torque is obtained.

The pain points of choosing worm gear grease:

1. The wear resistance and life of the grease cannot meet the application requirements

2. The grease will become soft or dry under long-term high temperature work

3. Worm gears are prone to wear, and the anti-wear and lubricating properties of the grease cannot meet the requirements

4. The current rises and the number of revolutions decrease when the grease starts at low temperature

Baoxing Lubricant Company's low temperature grease BX-300/F series, this grease has a variety of anti-extrusion and anti-wear additives, and is a low-temperature resistant gear grease refined by a special process. It can overcome high-speed centrifugal force, and is specially developed to meet the lubrication and noise reduction of worm gear reducer under high-speed operation. It has temperature stability, wear resistance and noise reduction. In addition, the BX-300/B series has high-quality lubrication performance, which can effectively reduce friction and current.

Dongguan Baoxing Lubricant Co., Ltd. has been focusing on the research and development of lubricants and greases for 13 years in various industries. The industry has mature experience and cooperates with customers across the country, reaching 10,000. Welcome to call our salesperson for consultation and provide free sampling.